How many types of blasting nozzles are there

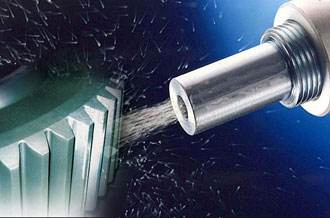

There are Two Main Blast Nozzle Shapes to Choose From: Straight Bore: It creates a uniform compressive force from the nozzle out to surface. Venturi Type: It is a nozzle that compensates the loss of pressure. It is narrow from the ejection to give full pressure ...

An air blasting nozzle is a device that accelerates air and an abrasive blasting mixture over a material's surface that exhibits pitting and needs repair and subsequent protection from corrosion. The nozzle's length and tapered design determine the pattern and velocity ...

What is boron carbide used for

boron carbide, (B4C), crystalline compound of boron and carbon. It is an extremely hard, synthetically produced material that is used in abrasive and wear-resistant products, in lightweight composite materials, and in control rods for nuclear power generation ...

Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic and covalent material used in tank armor, bulletproof vests, engine sabotage powders, as well as numerous industrial applications ...

Boron carbide, like tungsten carbide, is used in many kinds of machinery to make tools and other kinds of hard wearing equipment. This method uses a lot of energy and time, making boron carbide products up to 10 times more expensive than other, less hard wearing ...

Abrasive blasting is using pressurized air or water to propel abrasive media against a surface to remove coating, corrosion, or contamination. Also known as sand blasting, grit blasting, or media blasting, abrasive blasting is used to: Make a rough surface smooth ...