Property | Data |

Thermal Conductitivy(W/m·K) | ≥170 |

Dielectric Strength (1MHz) | 8.8 |

Flexural Strength (MPa) | >300 |

Vickers Hardness (GPa) | 11 |

Modules of Elasticity (Young) (GPa) | >200 |

water absorption (%) | 0 |

Volume Resistivity (Ω·cm)20℃ | >1014 |

Volume Resistivity (Ω·cm)300℃ | 109 |

Volume Resistivity (Ω·cm)500℃ | 107 |

Thermal Expansion Cofficient (/℃) | 4-6×10-6 |

| Density (g/cm3) | ≥3.30 |

| powder purity | Metal impurity content≤0.05Wt%,oxygen content ≤1Wt%,carbon content≤0.05Wt% |

| Dielectric Strength (KV/mm) | 15-20 |

Aluminum Nitride Ceramic Components Application:

• Components for semiconductor equipment

• IC packaging

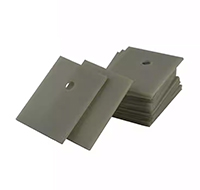

• Thermal module substrate

• High power transistor module substrate

• High frequency device substrate

• Exothermic insulation board for Thyristor Modules

• Semiconductor laser, fixed substrate for light emitting diode (LED)

• Hybrid integrated module, ignition device module

• Used in the sintering of structural ceramics

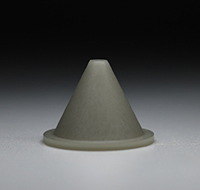

• AlN Crucible for Metal Melting & Electronic cigarettes

• Applied to luminous materials

• Applied to the substrate material